Featured Projects

Our pioneering projects

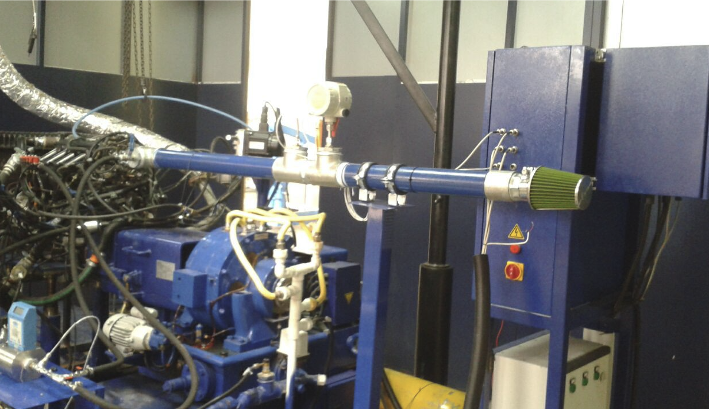

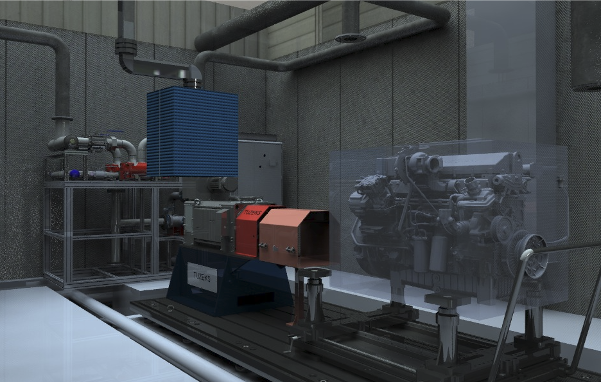

Marine & Tank Engine Testing Laboratory

Turkey’s first and only 10,000 HP diesel engine R&D testing laboratory. National engine development infrastructure for the MILGEM-class corvettes.

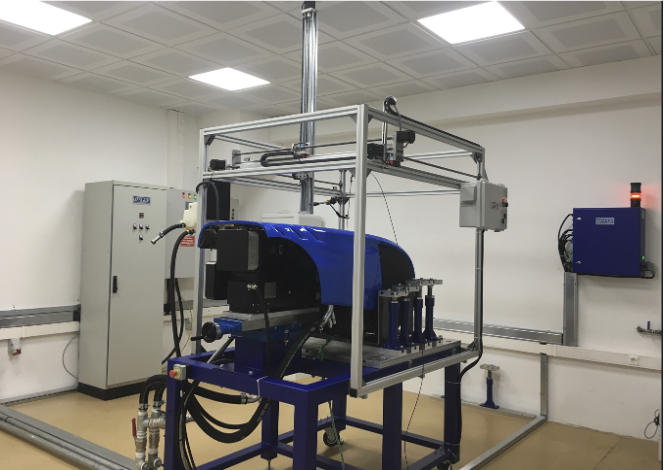

Climatic Test System

Versatile testing laboratory capable of temperature conditioning between -40°C and +60°C, enabling tractor testing via PTO loading.

Towing Dynamometer

Turkey’s first towing performance testing system designed for tractor drawbar tests. Fully compliant with ISO 789-9 and OECD Code 2 standards.

PTO Test System

A test laboratory where tractors’ performance parameters at the PTO output are verified and certified to standards by simulating real field load conditions.

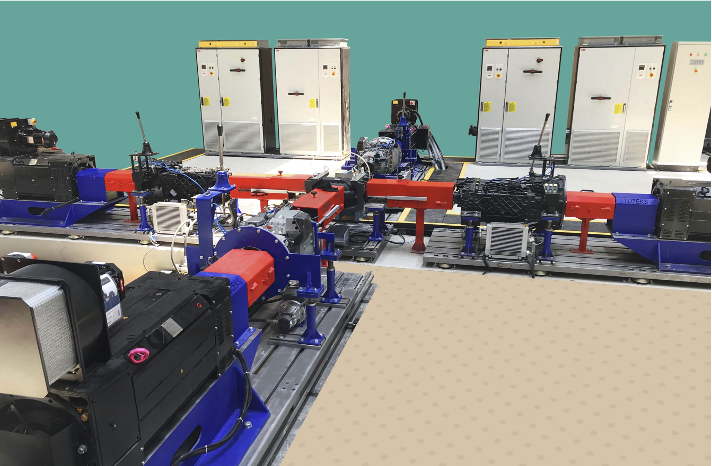

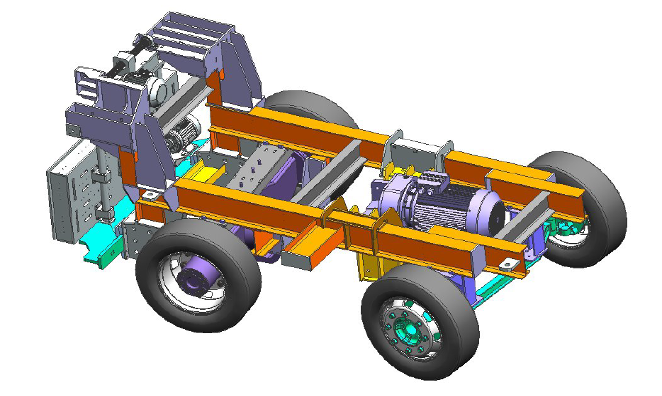

Transmission R&D Test System

A defense industry R&D laboratory where all dynamic parameters of armored vehicle transmissions up to 8x8 drivetrains and 550 kW power are tested under load.

End-of-Line Engine Test System

Production end engine testing infrastructure equipped with 3 parallel systems for 3–6 cylinder Farmotion engines, with testing capability up to 300 HP.

End-of-Line Engine Test System

At SDF Group’s facility in Turkey, an advanced engine testing infrastructure with three side-by-side installed systems for post-production testing of 3–6 cylinder Farmotion engines, with capacity up to 300 HP.

Transmission R&D and Durability Test Room

Built for tractor transmission development, this room simulates an ICE using a 175 kW drive dynamometer and can apply up to 90,000 Nm torque. Used for R&D and durability tests.

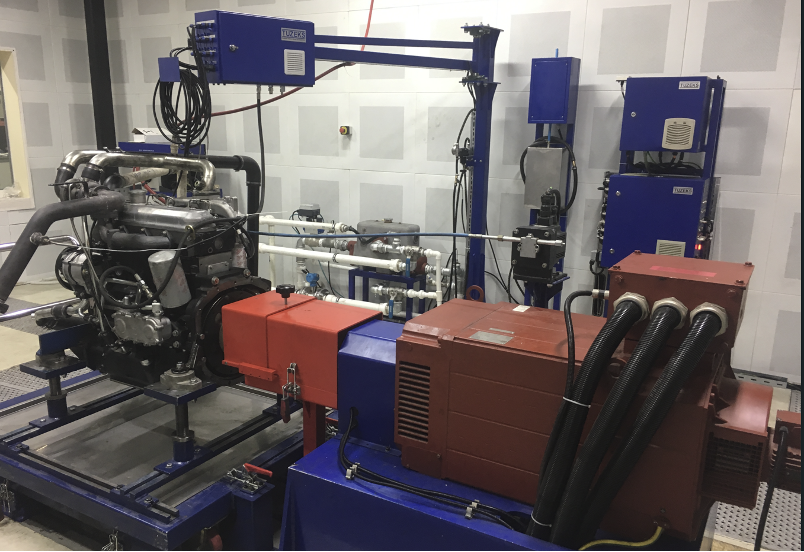

Engine R&D Durability & Emission Test Room

This room enables R&D and durability testing of engines up to 175 kW, along with emission measurements. Dynamic tests are also possible thanks to the active dynamometer.

Underhood Flow Test System

Established to analyze the effects of underhood air flow on fan and radiator performance, this system simulates real vehicle conditions to inform engineering design. Fan–radiator distance and coolant temperature scenarios can be tested.

Engine Test System

An academic, research-focused engine testing infrastructure enabling tests of engines up to 100 kW, including combustion chamber analysis capabilities.

University Engine Test Facility

An academic infrastructure suitable for testing gasoline and diesel engines up to 100 kW, enabling alternative fuel experiments; supports emission testing with CNC and LPG consumption measurements.

University Engine Test System

The engine test system being established within the university is currently in manufacturing and assembly. The goal is to build a modern academic and R&D infrastructure.

Bump Test System

The Bump Test system for vibration and mechanical shock endurance tests is planned to be commissioned in 2025 and is currently in manufacturing.